It is recommended that a prime and continuous diesel generator is run at around 60-75% of its maximum rated load. A set should never be run with no load for longer than 15 minutes at a time, and you will need to follow manufacturer guidelines to know how long you can run your generator with a low load (<60% of maximum rating). It’s crucial to get the right size generator for your application (Which kVA do I need?), too small and you won’t power up your operation, or too big and you can risk damaging the generator.

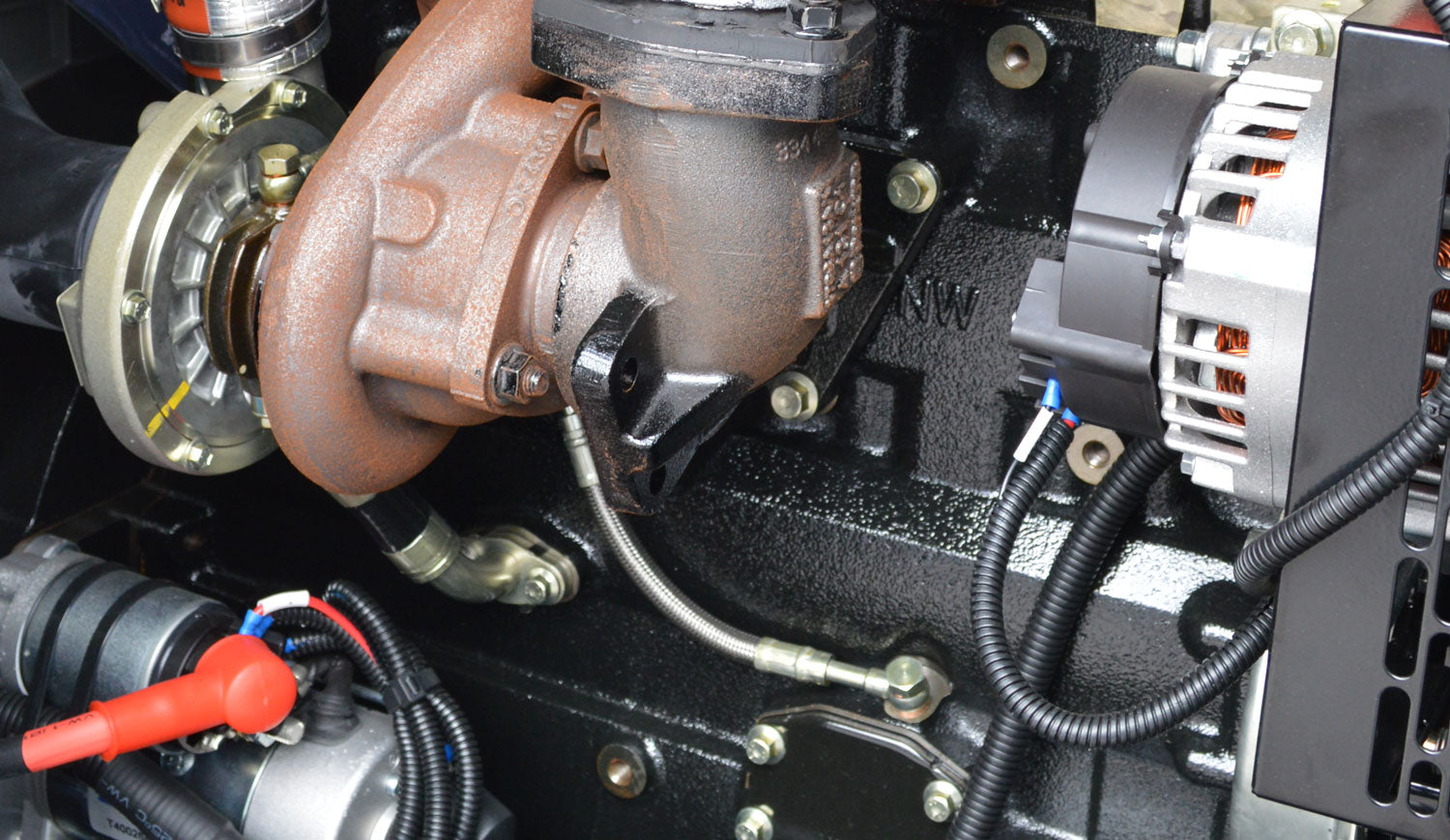

Problems caused by underloading include:

- Poor combustion

A reduction in scavenging air pressure negatively affects combustion efficiency and can lead to carbon deposits and thermal load on the piston assembly - Low cylinder pressure

- Reduced piston ring sealing

- Glazing

Poor combustion and low cylinder pressure combined can cause the unburnt fuel to form a thick, treacle like substance which is then baked on to the cylinders with heat - Decreased efficiency

- Increase in exhaust ‘white’ smoke

- Carbonised oil deposits on the engine valves, pistons, and exhaust system

- Higher oil consumption

Once glazing has occurred the generator will have reduced output and likely fail to start.

How to prevent damage from underloading a generator

- To reduce the risk of damage you can make sure that the generator you buy is the correct size for the application.

- Regular load bank testing at full rated capacity will enable the generator to reach operational temperature, burn up the fuel and eliminate issues such as wet stacking. (What is generator load bank testing and why do we need to do it?)